Ok, I've been running around all week....but here's some pics as promised!

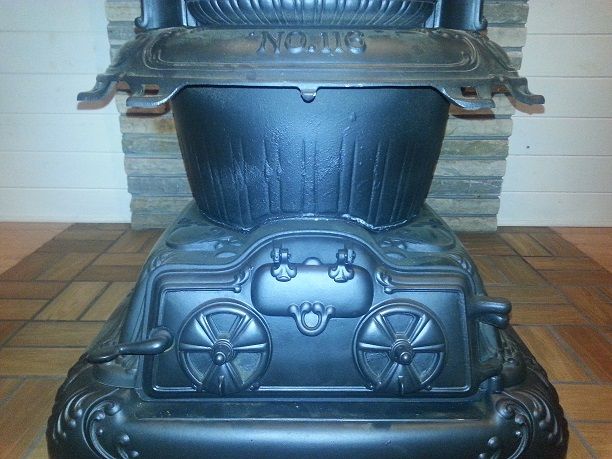

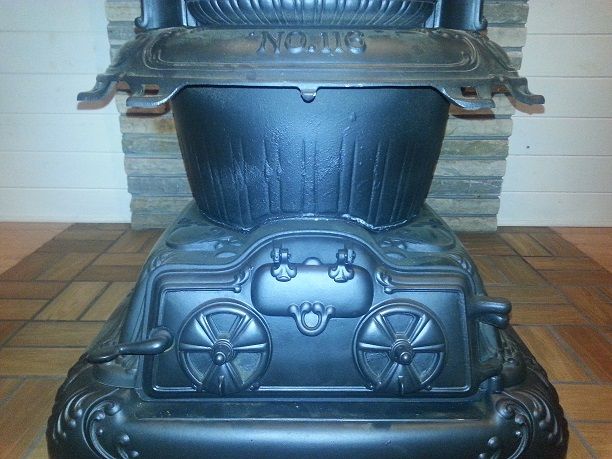

Here she is as she'll sit...without the shine, of course. I dropped off the pieces to get plated last Friday and should have them in about two weeks.

A nice, thick layer of refractory material waiting to get burned in!

The new pot, recast by Tomahawk. I didn't bother to take the casting flash off...that's my fault. Maybe I'll tackle that next year and repaint...maybe I won't - you barely see it when the skirts are off, and don't at all when they're on.

Emery made a brand new flue column, as the old one was seemed on the wrong side and, as he informed me, was also made of galvanized steel...glad I never used it. The original internals were reused.

So here's my dilemma. I originally told Emery that I was going to shoot the flue straight up, as the old pipe was made, seeing how I had a good rise to overcome as seen above. I'm reconsidering now, and thinking I might go straight out the back of the column, run a 90° up and another 90° straight out as I've seen most of you have done. I'm confident I can cut down the column to the correct height and fabricate a cap. What I'm having a problem deciding is how to run the pipe. As you can see, the clearance to the ceiling is at minimum, so I need the top elbow and straight pipe to be double walled, per code. I don't want to run DW pipe the full length for I know that will decrease the heat transfer. So I need some opinions and advice.

So, without further ado, the question session:

First - The hole through the masonry is 8", with no relief in the masonry...I know these stoves (at least my model) have a 6" exit at the column. So do I run an increaser near the column and run 8" from the bottom elbow up or put the increaser at the masonry and run 6" the full length?

Second - Does anyone know if there's anything fancy made to go from single wall to double wall? The lower elbow and vertical pipe will be SW and the upper elbow and horizontal to the masonry will be DW. I can't seem to find anything to make it look pretty, and am on the verge of succumbing to there being a stepped joint at the bottom of the upper elbow.

Third - With nothing to secure the pipe going into the masonry, would it be sound advice to run a reasonable length of 8" SW (maybe 6-8" with a minimal amt to affix to) into the masonry to give the DW adapter or straight pipe to screw onto?

Fourth - For the SW pipe: Snap-lock or welded?

Fifth - Is it worth it to install a damper in the vertical pipe?

Lastly - I'll be using furnace cement regardless, but crimps up or down with coal? I know they're supposed to be down with wood...didn't know if there's a difference.

Any and all responses are much obliged! All you guys have helped me out a bunch just by posting here, whether you know it or not! Thanks!!