Hello Everyone,

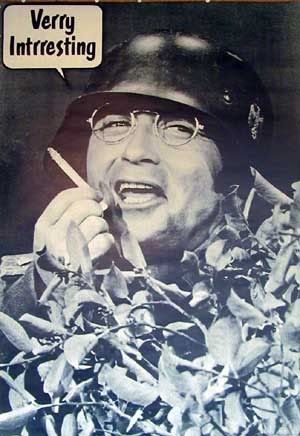

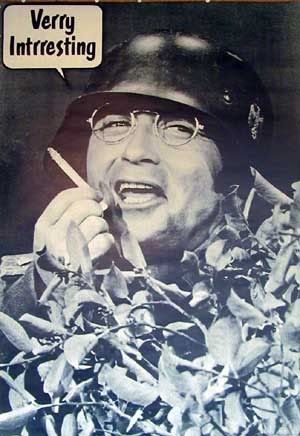

Have a EFM 520, Hot water base board, with two zones.....Having problems holding the temperature, especially it the one zone....The temp. is holding around 65 deg. and will not cool down, even then the therostat is set at 50 deg.....I replaced both thermostats, with no change, I can turn the thermostats up and the circulator will kick on and off. One thing that I noticed is that the zone I'm having most of the problems with, the supply is always hot, like it's being gravity feed...(see attached photo).

Thats in advanced,

Jim

Temperature Problems

- AA130FIREMAN

- Member

- Posts: 1954

- Joined: Sat. Feb. 28, 2009 4:13 pm

That is a flo check, it prevents ghost flo. Inside it's a brass barrel that raises on a stem off a seat, when the circulator runs, and "should" drop by gravity. Might be stuck open. There is a thumb screw on the top to raise (open) the flo check, you could try to raise it with an allen wrench in the thumbscrew then turn it down.

-

maverick784

- Member

- Posts: 25

- Joined: Wed. Oct. 10, 2012 10:38 pm

Thanks Fireman.....That valve had been open and I closed it....I will try opening and closing it a couple of times, see if that works.....Typ. this valve should be closed... Correct?

Thanks Again,

Thanks Again,

- Rob R.

- Site Moderator

- Posts: 18004

- Joined: Fri. Dec. 28, 2007 4:26 pm

- Location: Chazy, NY

- Stoker Coal Boiler: EFM 520

- Hand Fed Coal Stove: Chubby Jr

That flow-check should be closed when the circulator isn't running, so what you are experiencing doesn't happen. Maybe a few "light" taps will loosen it up.

-

maverick784

- Member

- Posts: 25

- Joined: Wed. Oct. 10, 2012 10:38 pm

Thanks Rob.....I guess the key word here is "Light"....I'll give that a try.

Thanks Again,

Thanks Again,

- AA130FIREMAN

- Member

- Posts: 1954

- Joined: Sat. Feb. 28, 2009 4:13 pm

Why was it open ? They are opened manually to bleed the air out when flushing the system, or if gravity flo is wanted if a circulator doesn't work.maverick784 wrote:That valve had been open and I closed it....

-

maverick784

- Member

- Posts: 25

- Joined: Wed. Oct. 10, 2012 10:38 pm

The house had been winterized before I purchased it........I had tried opening it and closing in and also tapping on it, but no luck.....Any other

options to try? If not, will this hurt anything or burn more coal?

options to try? If not, will this hurt anything or burn more coal?

- Sting

- Member

- Posts: 2983

- Joined: Mon. Feb. 25, 2008 4:24 pm

- Location: Lower Fox Valley = Wisconsin

- Other Heating: OBSO Lennox Pulse "Air Scorcher" burning NG

Discovering issues on a wet system that sat drained for some time can be "interesting"

B?G flow checks tend to stick in the last position and that would/should have been closed

if its stuck open - you may need more than a gentle tap to swing it to seat again - It may need to be back flushed - it may need to be taken apart

I have had issues with gravity flow just being too strong and weight needed to be added - This can be done by wrapping solder around the top of the check weight.

since we have no history of the system performance

the only correct answer is

It Depends!

check this link - about page 3

http://documentlibrary.xylemappliedwater.com/wp-c ... 51842E.pdf

B?G flow checks tend to stick in the last position and that would/should have been closed

if its stuck open - you may need more than a gentle tap to swing it to seat again - It may need to be back flushed - it may need to be taken apart

I have had issues with gravity flow just being too strong and weight needed to be added - This can be done by wrapping solder around the top of the check weight.

since we have no history of the system performance

the only correct answer is

It Depends!

check this link - about page 3

http://documentlibrary.xylemappliedwater.com/wp-c ... 51842E.pdf

- GoodProphets

- Member

- Posts: 226

- Joined: Sat. Jan. 07, 2012 9:14 pm

- Location: Lanc Co PA

- Stoker Coal Boiler: EFM DF520

- Coal Size/Type: Anthra Rice

- Other Heating: 3 Fireplaces

Is the heat on that zone constant?

Check your dump zone and temps.

May be dumping at a lower temp than necessary...is the circ pump cycle on at all with that zone?

Depending on the situation, does it need to cycle to keep at 50f?

Is is possible to disconnect the circ pump and turn a shut off valve to stop flow?

Check your dump zone and temps.

May be dumping at a lower temp than necessary...is the circ pump cycle on at all with that zone?

Depending on the situation, does it need to cycle to keep at 50f?

Is is possible to disconnect the circ pump and turn a shut off valve to stop flow?