Anthracite and water filtration

- freetown fred

- Member

- Posts: 30302

- Joined: Thu. Dec. 31, 2009 12:33 pm

- Location: Freetown,NY 13803

- Hand Fed Coal Stove: HITZER 50-93

- Coal Size/Type: BLASCHAK Nut

Outstanding pix J!!!!!!!!!!!!!!!!!! Nice find

- Sunny Boy

- Member

- Posts: 25756

- Joined: Mon. Nov. 11, 2013 1:40 pm

- Location: Central NY

- Hand Fed Coal Boiler: Anthracite Industrial, domestic hot water heater

- Baseburners & Antiques: Glenwood range 208, # 6 base heater, 2 Modern Oak 118.

- Coal Size/Type: Nuts !

- Other Heating: Oil &electric plenum furnace

Many years ago, my brother and I sank a new well in his Yaphank L.I. house basement.

We used a cast lead weight sliding on a rod to ram the well pipe down. He mounted a pulley over where he wanted the well, backed his Ford 8N tractor up to the basement window. Jacked up the back wheel and bolted a car wheel to it to act as a winch drum.

Then ran a rope from the lead weight, through the pulley and out the window to a couple of turns around the tractor winch drum. Putting a slight pull on the rope end, the tractor winch lifted the lead weight. When he'd slacken tension on the rope, the weight slide down a rod placed in the top of each section of well pipe and drove the pipe into the dirt. Took us longer to set up than to drive 25 feet of new well point.

With most of Long Island being sandy soil it was easy. With all the rocks here in CNY soil, that method would only work for about the first foot.

Paul

We used a cast lead weight sliding on a rod to ram the well pipe down. He mounted a pulley over where he wanted the well, backed his Ford 8N tractor up to the basement window. Jacked up the back wheel and bolted a car wheel to it to act as a winch drum.

Then ran a rope from the lead weight, through the pulley and out the window to a couple of turns around the tractor winch drum. Putting a slight pull on the rope end, the tractor winch lifted the lead weight. When he'd slacken tension on the rope, the weight slide down a rod placed in the top of each section of well pipe and drove the pipe into the dirt. Took us longer to set up than to drive 25 feet of new well point.

With most of Long Island being sandy soil it was easy. With all the rocks here in CNY soil, that method would only work for about the first foot.

Paul

- joethemechanic

- Member

- Posts: 369

- Joined: Sat. May. 23, 2015 12:26 pm

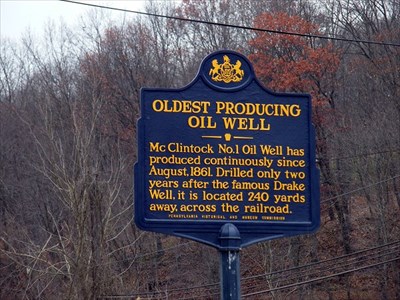

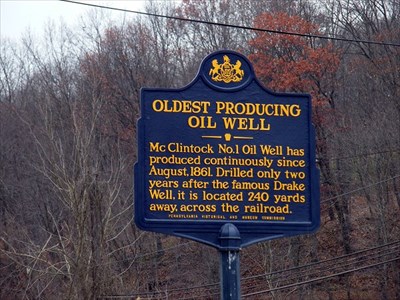

I am pretty sure this well was "Kicked Down".

On August 16, 1861, the McClintock No. 1 was kicked down to a depth of 200 feet and brought in its first oil for Brewer Watson & Company. One hundred and fifty years later that same well is still producing Pennsylvania crude oil, making it the oldest continuously producing oil well in the world.

-

leward

- Member

- Posts: 129

- Joined: Fri. Jul. 03, 2009 2:41 pm

- Location: Clearfield County, PA

- Stoker Coal Boiler: EFM520

- Hot Air Coal Stoker Stove: Hitzer 50-93 at camp

- Hand Fed Coal Stove: Hitzer 354 double door woodburner

Gents -- I worked for a company who built water treatment plants where we built these filters.

Typically there would be 4 "bays" - all built the same, that way some could be used while other were cleaned.

These filters had air chambers underneath, and layers of @b stone, 1B stone, masonry sand, garnet sand and anthracite coal layered in. The multiple layers were built so that these wouldn't choke off from sediment. If I remember correctly the garnet sand was on bottom, next 2B stone, 1B stone masonry sand and lastly the anthacite on top. After a set period of time ( or gallon flow) a huge air compressor would kick on, valves close, and the air would be blown up through from the bottom. The garnet sand "scrubbed" the gunk off of all the other media layers, and when the air was shut off, the materials would all settle back down in their respective order because of the specific gravity of each.

These were mostly built where there was a giardia problem (beaver fever) on a surface water source. Membrane filter were otherwise used for well systems. These systems worked great, but were costly. The coal was just a media that had tons of surface area being a crushed product. Much coarser than sand, but smaller than rice coal. We would get it in in super sacks. They are still being built as appropriate for the water system. The ones I worked on are still in use

Typically there would be 4 "bays" - all built the same, that way some could be used while other were cleaned.

These filters had air chambers underneath, and layers of @b stone, 1B stone, masonry sand, garnet sand and anthracite coal layered in. The multiple layers were built so that these wouldn't choke off from sediment. If I remember correctly the garnet sand was on bottom, next 2B stone, 1B stone masonry sand and lastly the anthacite on top. After a set period of time ( or gallon flow) a huge air compressor would kick on, valves close, and the air would be blown up through from the bottom. The garnet sand "scrubbed" the gunk off of all the other media layers, and when the air was shut off, the materials would all settle back down in their respective order because of the specific gravity of each.

These were mostly built where there was a giardia problem (beaver fever) on a surface water source. Membrane filter were otherwise used for well systems. These systems worked great, but were costly. The coal was just a media that had tons of surface area being a crushed product. Much coarser than sand, but smaller than rice coal. We would get it in in super sacks. They are still being built as appropriate for the water system. The ones I worked on are still in use

Here's a report that features our Ripley NY slow sand filter installed

in 1990 . It won an " National Environmental Achievement Award".

https://www.prwa.com/sites/default/files/files-we ... onetap.pdf

It produces a very high quality drinking water with water from a reservoir

which is supplied from a dam on a creek which collects water when the runoff

is available. It is on pages 11-16.

BigBarney

in 1990 . It won an " National Environmental Achievement Award".

https://www.prwa.com/sites/default/files/files-we ... onetap.pdf

It produces a very high quality drinking water with water from a reservoir

which is supplied from a dam on a creek which collects water when the runoff

is available. It is on pages 11-16.

BigBarney