High winds high heat chimney questions

- McGiever

- Member

- Posts: 10130

- Joined: Sun. May. 02, 2010 11:26 pm

- Location: Junction of PA-OH-WV

- Stoker Coal Boiler: AXEMAN-ANDERSON 130 "1959"

- Hand Fed Coal Boiler: BUCKET A DAY water heater

- Hand Fed Coal Stove: Warm Morning 414A

- Coal Size/Type: PEA,NUT,STOVE /ANTHRACITE

- Other Heating: Ground Source Heat Pump and some Solar

Hitting below .03 can happen with or without the baro...makes no difference either way.

Being below -.03 doesn't give house CO

Sure, raise chimney more.

Being below -.03 doesn't give house CO

Sure, raise chimney more.

- McGiever

- Member

- Posts: 10130

- Joined: Sun. May. 02, 2010 11:26 pm

- Location: Junction of PA-OH-WV

- Stoker Coal Boiler: AXEMAN-ANDERSON 130 "1959"

- Hand Fed Coal Boiler: BUCKET A DAY water heater

- Hand Fed Coal Stove: Warm Morning 414A

- Coal Size/Type: PEA,NUT,STOVE /ANTHRACITE

- Other Heating: Ground Source Heat Pump and some Solar

Have you ever witnessed any downdrafts in the Hitzer?

Did you ever see your mano go positve with a fire burning?

If recent high winds did not create any down drafts, do you think you're safe now?

What are you worried about?

Did you ever see your mano go positve with a fire burning?

If recent high winds did not create any down drafts, do you think you're safe now?

What are you worried about?

- CoalisCoolxWarm

- Member

- Posts: 2323

- Joined: Wed. Jan. 19, 2011 11:41 am

- Location: Western PA

- Stoker Coal Boiler: Keystoker KA-6

- Hand Fed Coal Furnace: old Sears rebuilt, bituminous- offline as of winter 2014

- Coal Size/Type: Anthracite Buckwheat

- Other Heating: Oil Boiler

Chimney height info

-

KingCoal

- Member

- Posts: 4837

- Joined: Wed. Apr. 03, 2013 1:24 pm

- Location: Elkhart county, IN.

- Hand Fed Coal Stove: 1 comforter stove works all iron coal box stove, seventies.

- Baseburners & Antiques: 2014 DTS C17 Base Burner, GW #6, GW 113 formerly Sir Williams, maybe others at Pauliewog’s I’ve forgotten about

- Coal Size/Type: Nut Anth.

- Other Heating: none

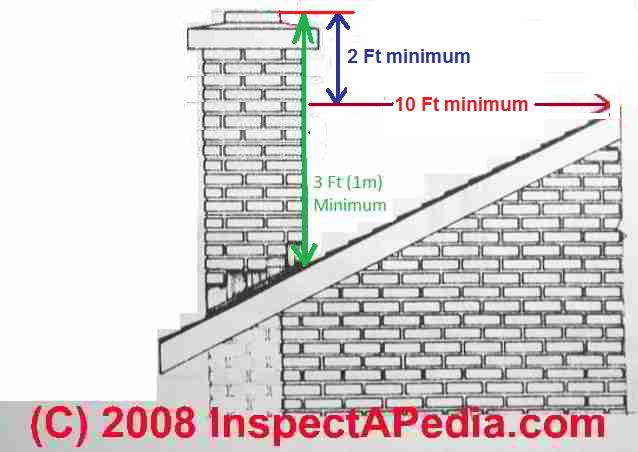

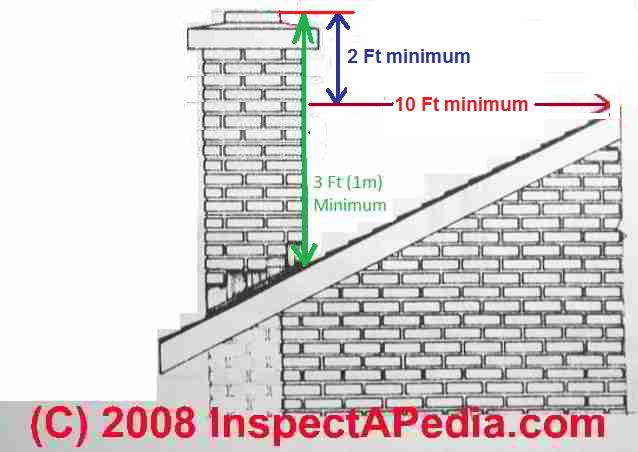

you could ad 2 ft of pipe to get the chimney top at or above 3Ft above the peak which will help more with down / up drafts than it will ad to what is perceived as draft force.

Hitzer are smart people and know what they are doing in recommending .03 - .06 if you run the stove on the bi metal alone you will pretty much always be in that area. unless you have high winds, then you will show more on the mano. but the bi metal flap will be staying open about the width of a piece of paper and so very little air will be moving thru the stove. point being it is not inferred that below -.03 you will automatically have a back draft.

this is the beauty of the bi metal, when the wind blows it closes off the air to keep the heat setting from being over run and when it's calm it opens more to hold the heat setting. when run this way it really doesn't matter what the mano numbers are.

since we know you will not likely ever have less than -.02 ( which is more than enough to keep the fire going ) then we can be sure it will be rare if ever that you have a sustained back draft.

there is info shared here about being able to run stoves with multiple times more exhaust path length than the Hitzer in the -.005 and under range for hours and days at a time.

best answer, call Hitzer and ask them what they think of a Baro. to deal with high wind on your installation, they are great people.

Hitzer are smart people and know what they are doing in recommending .03 - .06 if you run the stove on the bi metal alone you will pretty much always be in that area. unless you have high winds, then you will show more on the mano. but the bi metal flap will be staying open about the width of a piece of paper and so very little air will be moving thru the stove. point being it is not inferred that below -.03 you will automatically have a back draft.

this is the beauty of the bi metal, when the wind blows it closes off the air to keep the heat setting from being over run and when it's calm it opens more to hold the heat setting. when run this way it really doesn't matter what the mano numbers are.

since we know you will not likely ever have less than -.02 ( which is more than enough to keep the fire going ) then we can be sure it will be rare if ever that you have a sustained back draft.

there is info shared here about being able to run stoves with multiple times more exhaust path length than the Hitzer in the -.005 and under range for hours and days at a time.

best answer, call Hitzer and ask them what they think of a Baro. to deal with high wind on your installation, they are great people.

- oliver power

- Member

- Posts: 2970

- Joined: Sun. Apr. 16, 2006 9:28 am

- Location: Near Dansville, NY

- Stoker Coal Boiler: KEYSTOKER Kaa-2

- Hand Fed Coal Stove: Hitzer 50-93 & 30-95, Vigilant (pre-2310), D.S. 1600 Circulator, Hitzer 254

I was going to say ash pan vents, but seen it's been mentioned already. All assuming gaskets are good, of course...... No Need for Dampers. On the flip side, the stove did exactly what it's supposed to do. If the temps were colder, the wind would pull, closing the flapper door, and draw a little harder on the ash pan door vents. you'd be happy with the little extra heat. as it would be needed. Not sure where you have your ash pan vents adjusted to but, with these warmer temps, maybe you should close them up a little more....

In a way, installing a barometric damper hinders the operation of the Hitzer, and the way it has been engineered to operate. With a barometric damper installed, you will get a steady draw on the stove, No doubt. However, on a cold windy night, you may wake up to a cooler house, and want to open ash pan vents a little. So, which way would you rather have it when the temps drop. Wake up to a cooler house, and have to open ash pan (or primary) vents? Or wake up to a warm toasty house, because the stove operated like it was designed? I went back in posts, and seen you had the ash pan vents open to half moon. That's too much for the temps we've been having. Close them up to 1/16" open. As winter sets in, increase......... Once winter sets in, full moon is about right. Remember, every set-up is different. Just giving you general setting experience. Seen my old 50-93 in operation today. It sure is doing a fine job...

Call HITZER if you'd like. There are HITZER members that know the stove inside out, and backwards.

In a way, installing a barometric damper hinders the operation of the Hitzer, and the way it has been engineered to operate. With a barometric damper installed, you will get a steady draw on the stove, No doubt. However, on a cold windy night, you may wake up to a cooler house, and want to open ash pan vents a little. So, which way would you rather have it when the temps drop. Wake up to a cooler house, and have to open ash pan (or primary) vents? Or wake up to a warm toasty house, because the stove operated like it was designed? I went back in posts, and seen you had the ash pan vents open to half moon. That's too much for the temps we've been having. Close them up to 1/16" open. As winter sets in, increase......... Once winter sets in, full moon is about right. Remember, every set-up is different. Just giving you general setting experience. Seen my old 50-93 in operation today. It sure is doing a fine job...

Call HITZER if you'd like. There are HITZER members that know the stove inside out, and backwards.

Last edited by oliver power on Thu. Nov. 28, 2019 3:40 pm, edited 4 times in total.

-

scalabro

- Member

- Posts: 4197

- Joined: Wed. Oct. 03, 2012 9:53 am

- Location: Western Massachusetts

- Baseburners & Antiques: Crawford 40, PP Stewart No. 14, Abendroth Bros "Record 40"

- Coal Size/Type: Stove / Anthracite.

- Other Heating: Oil fired, forced hot air.

Regardless of the bi metal intake, if you have no means of DIRECTLY controlling excessive draft applied to the exhaust, you will lose heat up the chimney in any hand fired situation/installation.

No coal stove made is completely airtight on the primary side.

No coal stove made is completely airtight on the primary side.

Last edited by scalabro on Thu. Nov. 28, 2019 4:43 pm, edited 1 time in total.

- Spacecadet

- Member

- Posts: 278

- Joined: Sat. Feb. 10, 2018 9:36 pm

- Location: New Paltz NY

- Hand Fed Coal Stove: Hitzer 30-95, Hitzer 30/95

- Coal Size/Type: nut

- Other Heating: US stove 6041 pellet

Lots and lots on the baro posted here. I’ve been reading through all the info. My set up is ash door slide completely closed - always. I do have a baro and manometer. Sumer .02 draft not running. And I have the baro set to .05/.06 Today with the winds even with the baro flapping like crazy the manometer is bouncing from .04 to .15. And the box temp is higher than ‘normal’. The Hitzer paperwork I got with my used 30-95 when I got it said baro required. Honestly, without the baro I think I’d be having hot box issues like bluesdad is having.

I do totally agree that with a baro it is letting heated house air out and cool air is coming in from from all the tiny leaks. Like door and window seals and of coarse the wood pellet stoves fresh air vent.

Anyway, with the design of the bimetallic I can see how and why those don’t recommend the Overall. With the wind creating .15 draft i think I’ll keep the baro.

I do totally agree that with a baro it is letting heated house air out and cool air is coming in from from all the tiny leaks. Like door and window seals and of coarse the wood pellet stoves fresh air vent.

Anyway, with the design of the bimetallic I can see how and why those don’t recommend the Overall. With the wind creating .15 draft i think I’ll keep the baro.

- McGiever

- Member

- Posts: 10130

- Joined: Sun. May. 02, 2010 11:26 pm

- Location: Junction of PA-OH-WV

- Stoker Coal Boiler: AXEMAN-ANDERSON 130 "1959"

- Hand Fed Coal Boiler: BUCKET A DAY water heater

- Hand Fed Coal Stove: Warm Morning 414A

- Coal Size/Type: PEA,NUT,STOVE /ANTHRACITE

- Other Heating: Ground Source Heat Pump and some Solar

What is misunderstood here is that with this bimetallic damper it is closed.It doesn't matter one tiny bit if draft hits peaks of .15...or beyond, the bd is closed so nothing bad happens anyways. What's so hard about understanding this...

The doors and windows to your house have the same or worse peaks as your stove does, worry about them and never mind the stove.

My kitchen faucet has 60 psi there...so what...the valve is closed.

The doors and windows to your house have the same or worse peaks as your stove does, worry about them and never mind the stove.

My kitchen faucet has 60 psi there...so what...the valve is closed.

- oliver power

- Member

- Posts: 2970

- Joined: Sun. Apr. 16, 2006 9:28 am

- Location: Near Dansville, NY

- Stoker Coal Boiler: KEYSTOKER Kaa-2

- Hand Fed Coal Stove: Hitzer 50-93 & 30-95, Vigilant (pre-2310), D.S. 1600 Circulator, Hitzer 254

Exactly.....McGiever wrote: ↑Thu. Nov. 28, 2019 5:33 pmWhat is misunderstood here is that with this bimetallic damper it is closed.It doesn't matter one tiny bit if draft hits peaks of .15...or beyond, the bd is closed so nothing bad happens anyways. What's so hard about understanding this...

The doors and windows to your house have the same or worse peaks as your stove does, worry about them and never mind the stove.

My kitchen faucet has 60 psi there...so what...the valve is closed.

-

scalabro

- Member

- Posts: 4197

- Joined: Wed. Oct. 03, 2012 9:53 am

- Location: Western Massachusetts

- Baseburners & Antiques: Crawford 40, PP Stewart No. 14, Abendroth Bros "Record 40"

- Coal Size/Type: Stove / Anthracite.

- Other Heating: Oil fired, forced hot air.

McGiever wrote: ↑Thu. Nov. 28, 2019 5:33 pmWhat is misunderstood here is that with this bimetallic damper it is closed.It doesn't matter one tiny bit if draft hits peaks of .15...or beyond, the bd is closed so nothing bad happens anyways. What's so hard about understanding this...

The doors and windows to your house have the same or worse peaks as your stove does, worry about them and never mind the stove.

My kitchen faucet has 60 psi there...so what...the valve is closed.

Sorry gotta call BS, heat WILL be pulled up the chimney.

- Lightning

- Site Moderator

- Posts: 14669

- Joined: Wed. Nov. 16, 2011 9:51 am

- Location: Olean, NY

- Stoker Coal Boiler: Modified AA 130

- Coal Size/Type: Pea Size - Anthracite

We know that combustion air is brought into the stove by one force which is pressure. Pressure doesn't pull, although we tend to look at it that way, it's not what is fundamentally happening. Pressure moves from areas of high, to areas of low. Given this is fact, the only way a strong chimney draft pressure can "pull" heat out of a stove is if, and only if, it can be pushed out or be displaced by incoming air..

-

scalabro

- Member

- Posts: 4197

- Joined: Wed. Oct. 03, 2012 9:53 am

- Location: Western Massachusetts

- Baseburners & Antiques: Crawford 40, PP Stewart No. 14, Abendroth Bros "Record 40"

- Coal Size/Type: Stove / Anthracite.

- Other Heating: Oil fired, forced hot air.

Heat in the form of residual hot gasses will continue up the chimney as long as the chimney drafts. Regardless of the primary being setting.

Last edited by scalabro on Thu. Nov. 28, 2019 7:09 pm, edited 1 time in total.