A few months ago I said here that I have a patent, gravite fed stove for both coal and pellet.

I have completed all official documents and submitted to China Patent Bureau.

China is sponsoring member of PCT, my patent is under protect in American too.

Any patent pirate is severe crime

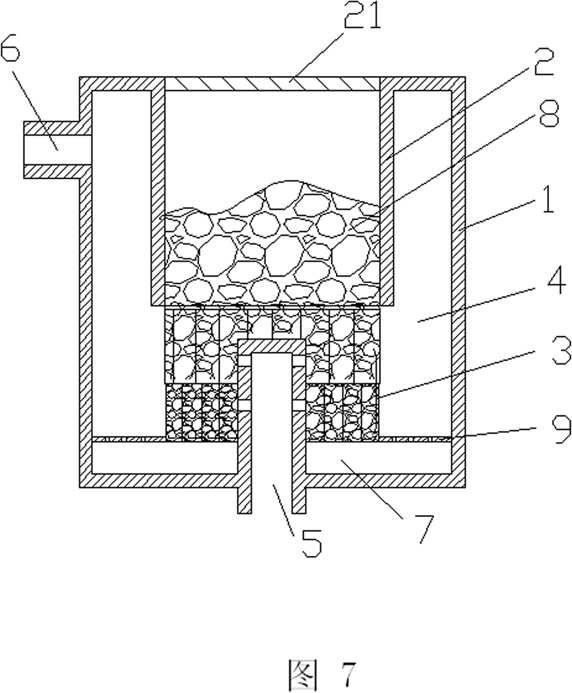

Item2:fuel bin

Item8:fuel

Item5: fresh air intake

Item6:flue

Item3: burning cage(s), one layer or more layers.

There are already several patents of gravity fed stove.

But all have fuel flow un-controlled.

There is horizontal distance between fuel bin and buring pot,which creats problem of fuel flow.

Fuel quantity is controlled by opening.

Either too many fuel or no fuel to burning pot.

The highligh of my patent is a burning cage(s).

Size of burning cage and fresh air intake tube define quantity of fuel burning.

An adjustable block inside burning cage can change effective size and in turn change fire.

There are one or more layers of burning cages.Each layer has different grate gap.

Smaller size fuel will fall to next layer to continue burning.

Fuel bin is directly above burning cage, there is no horizontal flow of fuel, no blocking worry.

Pre-heat effect can lower requirement of water content, then lower production cost of wood pellet.

Pre-heat effect also distills the fuel and helps cleanly burning.

I have tested wood pellet, corn, Anthracite and Bituminous Coal,

Wood pellet needs smallest cage. Indeed my idea is firstly for wood pellet.

Corn does not work. Pre-heat simply makes corn a big clinker, no flow down.

If fuel bin is moved to outside but right above of stove body, adding a controlled feeding opening, corn may burn too.If so it falls to traditional corn stove somewhat.

Bituminous Coal is some what like wood pellet, but needs bigger cage and more air intake.

Both wood pellet and Bituminous Coal can burn by simply flue.

Anthracite coal must need a blower and flue in my test. A better engineering optimization may be needed to cancel blower.

I am planning to transfer patent to major stove manufacturers, shall you have any interest, please contact:

Name:Wang ZhaoHui

Email:[email protected]

tel No.(86)13901185127